Ultrasonic Record Cleaning and Restoration Service

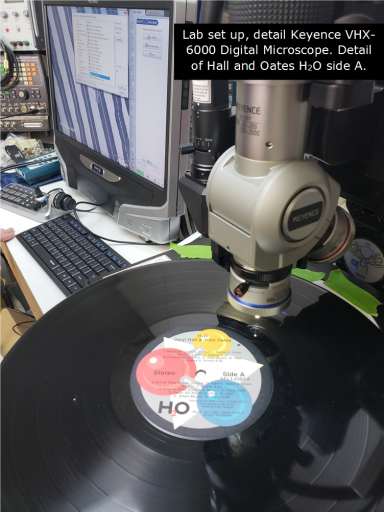

We are able to offer Kirmuss Audio KARC1 Ultrasonic cleaning of your records. Unlike other cleaning systems, the Kirmus Audio record restoration process leaves records virtually dry, proving the premise of the record’s PVC repelling water. No air or vacuum drying needed. Any droplets of water are removed by the supplied optician's lint free microfiber cloth.

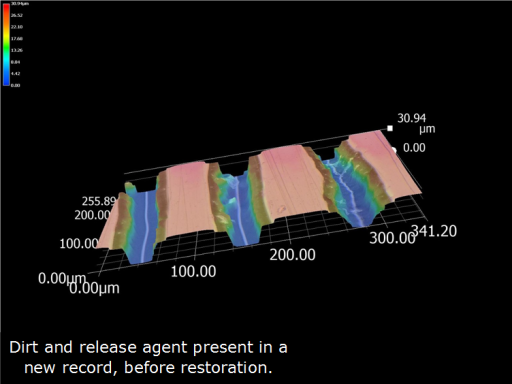

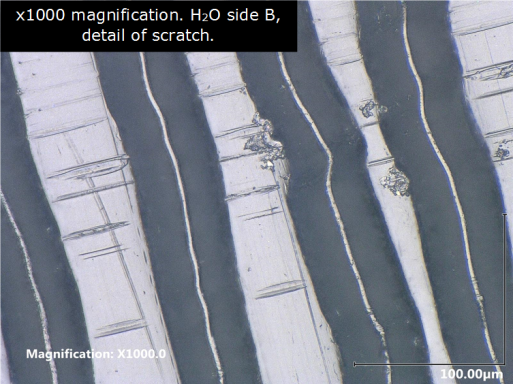

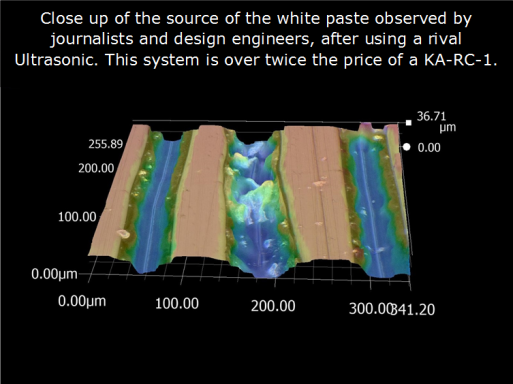

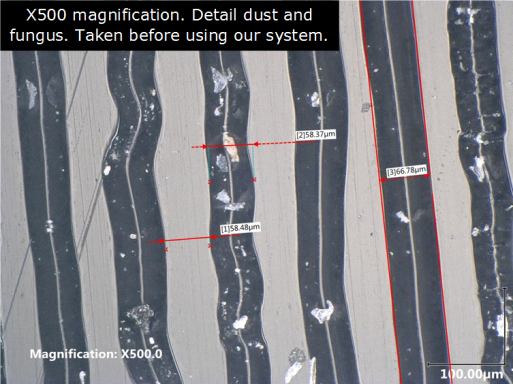

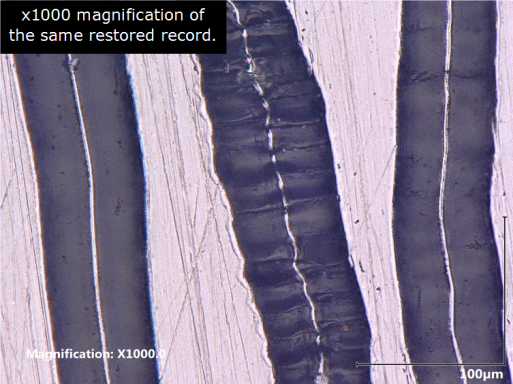

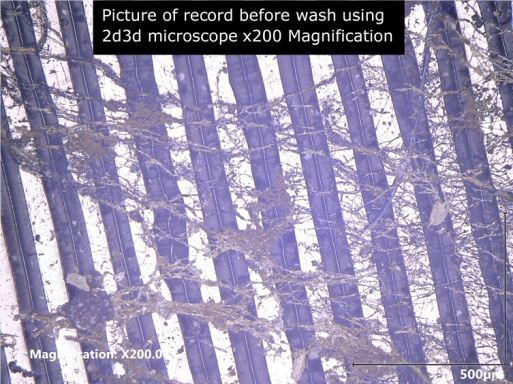

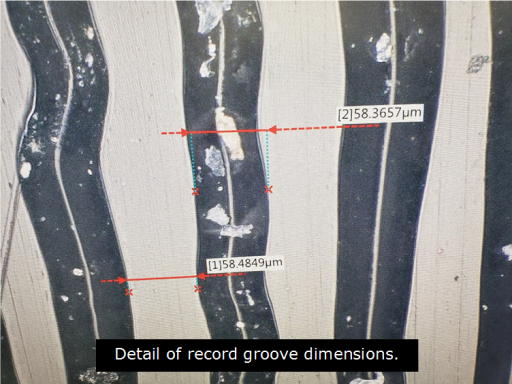

Over several cycles, we first remove films left over from prior cleaning processes, (that were air or vacuum dried onto the record), then the release agent (Pressing oil as discovered by the Shure Brothers, circa 1977), where dust and dirt at the pressing plant are fused into this cooling material, cause of those unwanted pops.

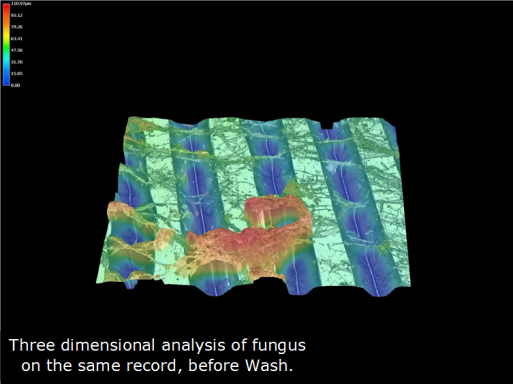

Our system removes release agents, micro-welded dust particles, fungus, and layers of previous cleaning system residues, thus restoring the record to its full potential.

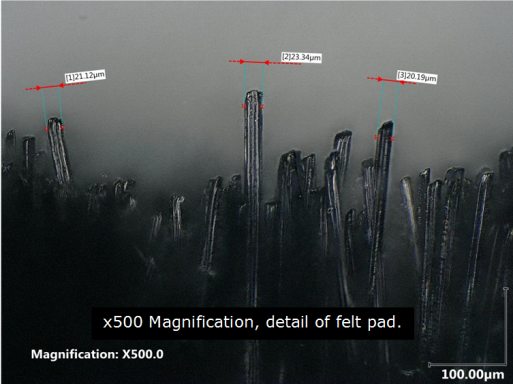

In our system, properly spaced records float safely and aren’t speared or squeezed (which damages the record and its label), a temperate distilled water bath is the “mechanical” cleaning action (plasma wave generated through cavitation), and a water-soluble and PVC-safe ionizing surfactant agent is sprayed onto the record’s surface to attract the plasma wave.

The temporary change of the record’s charge with respect to that of the water, as well as the multiple cycles with the repeatedly applied ionizing agent, removes from the grooves the aforementioned unwanted release agents.

A record is restored in four or five two- to five-minute cycles, and not just surfaced cleaned like with other processes.

It is the ultimate solution to preserving your valuable record collection, truly restoring and maintaining records at an affordable price. RESULTS ARE GUARANTEED!

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.